In our kitchens, a microwave oven is an indispensable appliance. It has become an integral part of our lifestyle. The convenience and affordability make the diffusion of microwave ovens unstoppable. According to Statista, the global revenue of microwave ovens is expected to be $7 billion in 2020, from the sale of 70 million units. Both volume and revenue are growing, without facing any limit. Among the underlying growth drivers, increasing disposable income, changing lifestyle, increased demand for ready-to-eat frozen food, and savings in energy and time are prominent ones. Interestingly, the idea of the microwave oven came out unintentionally. In 1945, Percy Spencer surprisingly observed a chocolate bar in his pocket turned into goo, while he was experimenting with microwaves at Raytheon. Subsequently, Raytheon started a long journey of invention and evolution of the microwave oven.

However, Spencer was not assigned to generate ideas for innovating kitchenware to heat food efficiently. Instead, he was experimenting with magnetrons, vacuum tubes that produced microwave radiation, for developing better RADAR for the US military. His accidental observation led to further experimentation with producing microwave radiation for cooking eggs and making popcorn with low radiation radars. Nevertheless, his employer, defense contractor Raytheon, showed interest and filed a patent in 1946. In 1947, Raytheon unveiled this great Innovation. However, it faced many barriers to reaching our kitchens. One of them was a health concern. In the beginning, many people believed that the microwave oven placed human beings on the path of slow death. Of course, the other one was a high cost.

Primitive emergence of microwave oven invention

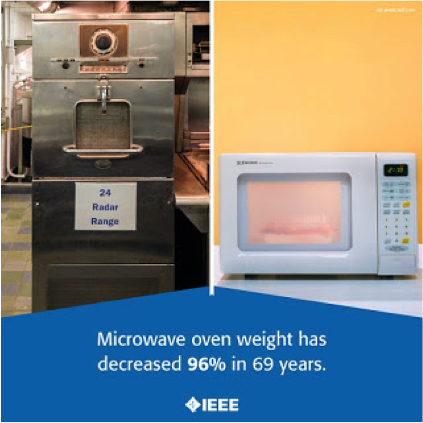

Like many other great innovations, the microwave oven also emerged in primitive form. It was very primitive indeed. It rolled out as a five and a half feet tall, weighing over 759-pound machines, costing $5000 each (a staggering $50,000 in today’s currency). Moreover, it needed a plumbing installation to cool the magnetron. This 3kw machine needed water cooling to prevented being melted from its own heat. Despite the high potential, this great innovation faced a high barrier to diffuse. The perceived value of this huge machine costing $5,000 for heating food a bit faster was not very high among most of the households. A handful of customers like ships, hotels, and trains found it worth paying. Despite charging a straggling price, Raytheon was not profiting from selling this machine either. This reality demanded a long journey of the invention of the microwave oven to succeed through evolution.

Incremental innovation is at the core of the evolution of the microwave oven

The long journey of incremental innovation started soon after its release. The goal was to make better as well as cheaper versions of it. The race of the refinement through ideas to reduce the size was critical to making the great idea succeed to serve target users’ purposes better and to produce profitable revenue for the producers. To make the first patent commercially successful, the refinement journey filed hundreds of additional patents. Dr. Spencer alone received 150 of them. The refinement processes experienced visible success with the ideas of a new air-cooled magnetron. It required no longer any plumber. As a result, it became more reliable and also made the oven lightweight. Subsequently, it became also less expensive to produce. Notably, in 1955, Raytheon released a slightly-less-bulky and cheaper version targeting home use. Nevertheless, it was still too big, and at $1,300, too expensive for mass use.

Change of technology core opened the entry for Japanese

The eventual Breakthrough came from the Japanese. In 1964, the Japanese succeeded with the invention of an efficient electron tube. It was far smaller and energy-efficient than Raytheon’s older, bulkier tubes called magnetrons. Subsequently, both Japanese makers and also Raytheon released a compact, countertop version. It was also far cheaper, retailing for $495, and cooked hamburgers in 35 seconds. In fact, this countertop machine started to diffuse in rapid space. Customers found that the machine’s economic attractiveness in saving energy and time was outweighing safety concerns. It also contributed to convenience.

But it started to face another barrier. Myths and fears surrounding these mysterious new electronic “radar ranges” started to surface. Subsequently, the fear of slow death in the microwave started impeding the adoption. However, the benefits of microwave cooking started to outweigh the possible risks. Hence, fear started fading away, swelling wave of acceptance. Moreover, the US Federal standards set in 1971 to resolve radiation risks added further momentum in driving the product’s acceptance.

The journey of improving microwave ovens also observed changes of other technology cores, having further positive implications on cost, quality, and convenience. For example, designers replaced the electromechanical control switch with an electronic-based user interface. This trend led to adopting a software-based user interface and heating control. Software-based heating control fueled innovations in heating patterns, making microwave ovens suitable for cooking food, homemade lasagna, and even making pizza. The recent addition of induction health coil has opened the use of microwave oven for baking cake and cookies, among preparing other food items.

Technology discontinuity led to the migration of business from American to Japanese

Japanese technology firm Sharp showed an early interest in Microwave ovens. The company saw the opportunity to use a microwave oven in Japanese family cooking, which relied heavily on reheating. But Raytheon’s large machine was not suitable for Japanese small houses and kitchens. Hence sharp became desperate to reinvent microwave tubes to make them far smaller and less energy-consuming. Sharp’s success led to the rapid diffusion of the microwave oven in Japan in the late 1960s. This technological breakthrough also empowered Japanese companies to take over the overseas market. With their compact, less costly microwave oven, they started harvesting a windfall when the world market took off, going from 600,000 ovens in 1970 to 2.2 million in 1975.

By 1979, Japanese companies took over 25% of the US market. Although in the late 1970s, GE began investing seriously in microwave ovens, it was too late. By 1997, 1997, 90% of U.S. households owned a microwave oven, and many of them were made by Japanese companies like Sharp.

In 1982, continued progression led the Japanese to begin to export a new midsize line of ovens at an alarmingly low price. Even, its retail price was lower than GE’s cost at its modernized plant. The rapid growth of the microwave oven market and Japanese firms’ success encouraged Korea’s Samsung to step into this lucrative market. After seven years of hard work, Korea’s Samsung outpriced America’s GE. In 1983, Samsun’s microwave oven cost only $155 as opposed to GE’s $218. The main difference was the cost of labor at assembling, material handling, and management level.

Japan’s focus on getting the job done better led to technology lead; and Samsung’s cost advantage made Asia succeed

The most important contrast came out from the fact that Samsung was paying less to workers but was getting far more. As opposed to GE’s four units per person each day, Samsung got nine. Furthermore, in comparison to GE’s $30 per oven for supervision, maintenance, and setup, Samsung was spending 73 cents. Without having any technology lead, due to this cost advantage, Samsung made an entry into the global microwave business. On the other hand, Japan succeeded with technology lead to snatch away the opportunity of profiting from American invention.

Instead of replicating or imitating, the Japanese focused on redesigning the microwave ovens to serve the purpose of reheating food in the Japanese Kitchen better. This is a vital strategic approach to succeed in innovation. This journey of getting the job done better through ideas of redesign led to the creation of Japanese successes in the microwave oven market. In fact, this has been at the core driving the invention and evolution of the microwave oven.

However, this journey of evolution has not stopped yet. Instead of using a microwave tube, the microwave oven is emerging using solid-state RF (radio frequency) energy to cook. Better control of projecting energy on food is resulting in improved consistency, taste, and nutrition. It’s expected that the solid-state device-based microwave oven will allow for controlling large amounts of energy with higher efficiency and with real-time feedback.

The lesson for Jugaad — grassroots and frugal innovations

Many of the frugal innovations or Jugaad in developing countries have lessons to draw from Microwave ovens. A single great idea does not succeed in developing large profitable businesses. Invariably, they appear in primitive forms. The relentless journey of continued progression is a must to exploit the hidden potential. This journey even may lead to changing the technology core. Moreover, a great idea may come from accidental observation or an act of tinkering, but it needs a scientific approach for further refinement.

Unfortunately, most frugal or grassroots innovations begin the journey out of tinkering, and they remain there. It’s time to realize the need for a scientific approach-driven relentless journey of perfection. Hence, even more than a quarter-million frugal innovations in India fail to develop collective success comparable to a single idea like a Microwave oven. Hence, a frugal innovation promoter should draw a lesson from the Invention and evolution of the Microwave Oven.