Why do we care about Process Innovation? Is it just for labor-saving? What is the secret recipe of TSMC in taking over Silicone edge from Silicon Valley? Besides, is not Product innovation good enough to turn great ideas into a profitable business?

Irrespective of the greatness of the ideas, no product innovation succeeds without the advancement of process innovation. For example, without the process of silicon processing capability like photolithography, mighty Transistor would have little power to unleash its might. Unfortunately, despite its immense importance, process innovation gets very little attention in the discourse of invention and innovation. In retrospect, Japan’s success in building a modern industrial economy hinges on automation and robotics driving process advancement. Another great example is Taiwan Semiconductor Manufacturing (TSMC). Furthermore, the massive job loss fear at the dawn of the Fourth Industrial Revolution is about process innovation, whether due to robotics on the factory floor or robotic process automation (RPA) for service production.

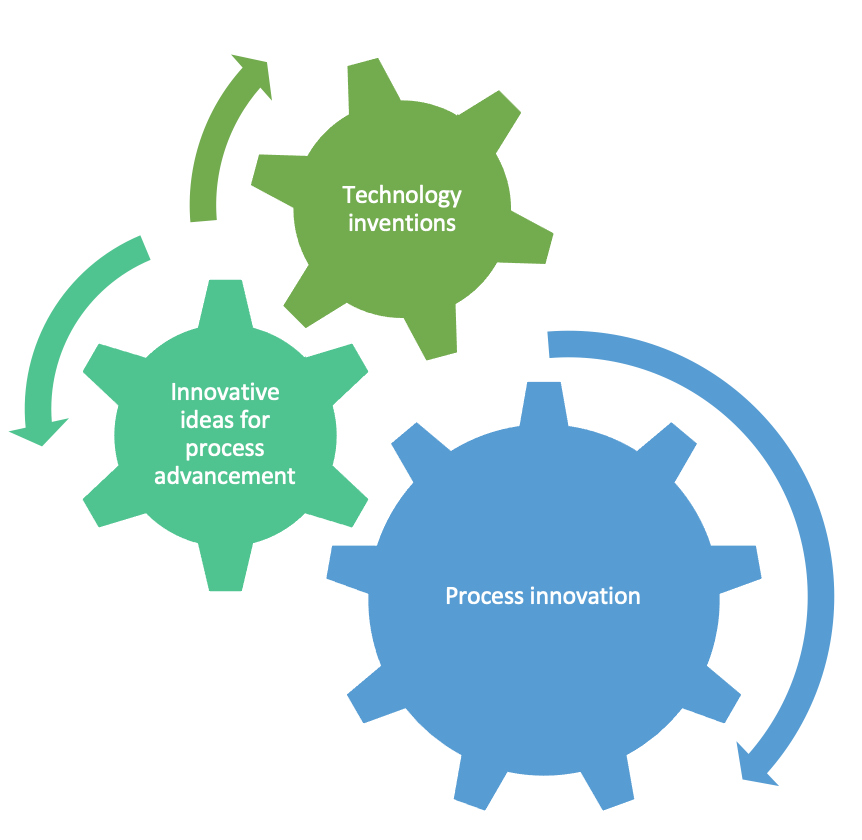

Every product, whether good or service, is produced through a process. Process innovation is about ideas for improving production processes. It creates value for both internal and external customers. Many key performance indicators such as quality, wastage, cost, lead time, and predictability are susceptible to advancement due to innovative process ideas. Values stemming from innovative ideas of process advancement play a significant role in competitiveness. Hence, although innovation focuses on product innovation, process innovation plays a vital role. Technology inventions form our core capability to generate ideas for process advancement. Some of the technology cores are job division, automation, and robotics. The continued improvement of the process has a natural tendency of automating Codified Knowledge and skill, leaving only innate abilities for humans to supply. Hence, process advancement affects the amount and type of labor demand in production.

Grassroots ideas and Craftsmanship kick start process innovation:

Often, production processes begin the journey from grassroots ideas and craftsmanship means for their implementation. Even the most sophisticated production processes have such roots. For example, the fabrication process of the first Transistor culminated through tinkering and craftsmanship. Upon showing initial efficacy, the accumulation of scientific knowledge and its use in systematic ideation begins. Besides, engineering starts taking over tinkering and craftsmanship for optimality.

For this reason, the modern semiconductor plant is far different than the one the scientists at the Bell Labs used to fabricate the first Transistor. Similarly, current automobile plants are pretty different than Carl Benz’s initial production process. On the service front, the scenario is the same. Over the centuries, production processes of services, whether financial or healthcare, have been progressing through process innovation—leading to robotic process automation.

Technology invention forms the core:

Like product innovation, process innovation largely depends on technology invention. For example, many technology inventions have been at the root of robotic process automation in service production. Similarly, the invention of electric motors, sensors, and microcontrollers are technology cores for manufacturing process innovation. Technology inventions fuel ideation for innovating process features, whether as new, replacement, or modification of existing ones. For example, the invention of photolithography technology has been fueling the innovation of semiconductor processing. As a result, the quality of silicon chips has been improving, while the cost per Transistor has been falling.

Business and manufacturing process innovation:

Both business and manufacturing production processes have been progressing due to innovation. For example, robotic process automation (RPA) has been automating humans’ cognitive capability in producing services. The technology invention has been supporting even speech recognition, synthesis, and face recognition. As a result, RPA has been taking over an increasing number of cognitive roles in service production. On the other hand, manufacturing processes have been observing increasing innovation in machine capability. Gradually, in both business and manufacturing processes, innovations have been empowering technology to take over a greater role.

Preindustrial age, mechanization, job division, and production line:

In the preindustrial age, a single artisan, whether carpenter or blacksmith, used to produce a whole product. A single artisan used to perform all the activities in producing a finished product. Hence, a single person was in charge of dividing the work into activities, organizing activities, and executing them by supplying energy, knowledge, skills, and innate abilities. However, the mechanization of the production process brought significant innovation in production. It was one of the drivers of the 1st industrial revolution. Subsequently, at the dawn of the 20th century, process innovation drew further attention due to job division and organization of productive activities as a production line. Like in past, the dawn of the 20th century has started experiencing process automation in service.

Automation and robotics for process innovation:

Technology inventions have enabled us to develop machine capability to take over manipulation, knowledge, and cognitive roles from humans. Automation began the journey due to the mechanization and steam engines during the first industrial revolution. Besides, it was mostly confined to the factory floor. But over the last 70 years, process innovators have made significant progress in automating the codified knowledge and skill of humans. On the other hand, robotic process automation has been manifesting in taking over knowledge and cognitive roles in service delivery.

Along the way, we have developed two major automation tools: physical robots and bots. Unlike physical robots working in factories, bots are software robots. These bots have been at the core of service production process automation. Hence, the population of both physical robots and bots has been growing. But the number of bots in operation is far more than 2.7 million robots working in factories in 2020. The major workforces of some global companies like Google, Facebook, or Twitter are bots. These bots have been working round the clock.

Process innovation for higher quality and lower cost:

Why are we after process innovation? Is it just for saving labor? Perhaps, No. Process innovation ideas focus on improving precision, lowering defects, and reducing wastage. Hence, these ideas lead to higher quality and lower costs. But in doing so, we need to delegate roles from humans to machines. Hence, process innovation has a natural tendency to reduce human roles in the production. But that is a consequential effect or byproduct.

Through a Flow of Ideas, systematic persuasion of process innovation has a long-run effect on competitiveness. Among many others, in the 1960s, Japanese firms took it very seriously. They looked into process innovation as a key area for developing an edge in producing diverse goods, from automobiles to toys. In addition to Deming’s quality lesson, they paid serious attention to improving process innovation. Hence, Japanese manufacturers formed a strong bond with automation and robotics companies. As a consequential effect, seven out of the top ten global robotic companies are from Japan. Being a late entrant, Japan has become a global leader in quality out of process innovation in many industries.

Process innovation for offshoring and reshoring:

As explained, process improvement through innovation focuses on automation and robotics for mimicking humans’ knowledge and skill in machines. As a result, humans’ role in supplying codified knowledge and skill has been falling, leaving only innate abilities for humans to supply in certain productions. Hence, humans without formal education, skill development training, and experience become eligible for factory jobs. To take advantage of it, multinational companies have relocated manufacturing plants in less developed countries to source low-cost labor, creating an offshoring phenomenon. But the further progression of process innovation is opening the possibility of automating humans’ innate ability, resulting in human free production. Hence, in the future, offshoring production activities will experience reshoring. Besides, business process outsourcing (BPO) jobs are already being taken over by RPA, creating massive job losses in BPO exporting countries like India and the Philippines.

Process innovation underpins the success of product innovation:

Despite the greatness of product ideas, process innovation plays a vital role in assuring quality and minimizing the cost of production. Hence, it’s no wonder that Apple has a strong role in process innovation for helping suppliers like Foxconn, giving birth to a quote “designed by Apple, built by robots.” As explained, for this reason, Japanese companies have a strong partnership with local automation and robotics companies. Without process advancement through ideas, no great product, whether goods or services, succeeds and sustains the successes in the globally connected competitive market.

Like product innovation, process innovation is equally important. With process innovation, even followers take the lead due to superior performance in quality advancement and cost reduction race. Hence, process innovation has become a core competence in the competition space. It’s not about just labor-saving. The focus is on advancing machine capability for advancing processes for improving the quality and reducing the cost. Of course, there is a consequential effect on labor demand. Without process innovation, no great product can succeed and sustain. Even a labor supplying firm or country can migrate to an Innovation Economy through process innovation.

...welcome to join us. We are on a mission to develop an enlightened community by sharing the insights of Wealth creation out of technology possibilities as reoccuring patters. If you like the article, you may encourage us by sharing it through social media to enlighten others.